Role of 3D Printed Medical Devices Ensuring Safety and Compatibility for implantable Devices

|

| 3D Printed Medical Devices |

Depending on the printing technique used and the intricacy of

the machines, there are a number of steps involved in creating 3D printed

medical devices. Medical equipment that is 3D printed can be customized to a

patient's particular demands and used to create anatomical models for medical

training and teaching. For decades, from research and development to

production, 3D printing has influenced the development of new products and

medical devices. In order to challenge the status quo of the healthcare sector,

more businesses are obtaining access to 3D printing as prices for printers drop

and investments in hardware and materials pick up speed.

The global 3D printed medical devices market is estimated to account for US$ 1,737.5 Mn in terms of value by the end of 2027.

Medical device producers and inventors can lower the price

and turnaround time of their products by bringing 3D printed medical devices

in-house. The innovation in final-use components, flexible product development,

and the capacity to make personalized medical devices—which are not possible to

make using conventional methods are all made possible by the technology. As

well as using 3D printed medical devices also makes it possible to create medical device prototypes

incorporating diverse materials in scenarios requiring properties such as

strength, flexibility, or heat resistance. Developing products has also been

revolutionized by the ease of use and low cost of 3D printing in-house. With

traditional manufacturing methods, the manufacturer faced high start-up costs

and lengthy operations associated with developing complex medical device

prototypes.

In addition to surgical guides, splints, temporary and

permanent restorations, and dentures, 3D printing is also a viable option for

creating dentures. A form of additive manufacturing is 3D printing. Although

additive manufacturing encompasses a variety of processes, the phrases 3D

printing and additive manufacturing are sometimes used interchangeably. For the

sake of convenience, we'll refer to those both as 3D printing here.

Through the use of successive layers of raw materials, 3D

printing produces objects that are three-dimensional. Up until the thing is

finished, each new layer adheres attached to the one before it. A digital

3D file, such as a computer-aided design (CAD) sketch or an MRI, is used to

create an object. The adaptability of 3D printing enables designers to easily

make adjustments without having to set up new tools or equipment. Additionally,

it enables manufacturers to design patient-specific devices that are tailored

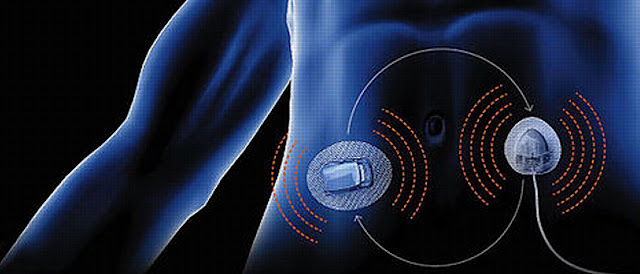

to a patient's anatomy. Implants, surgical instruments, dental restorations

such as crowns, and external prosthetics are some of the medical devices

produced by 3D printing.

Comments

Post a Comment