Liquid Silicone Rubber: The Versatile Solution for Industrial Applications

| Liquid Silicone Rubber |

In the realm of industrial materials, liquid silicone rubber (LSR) has emerged as a highly versatile and sought-after option. With its unique properties, LSR offers exceptional performance and flexibility in a wide range of industrial applications. From automotive and electronics to healthcare and consumer goods, this remarkable material has revolutionized manufacturing processes. In this blog, we will explore the characteristics, benefits, and diverse applications of liquid silicone rubber.

Exceptional Properties of Liquid Silicone Rubber is Liquid

silicone rubber is a two-part platinum-cured elastomer that transforms from a

liquid to a solid elastomer through a cross-linking process. It possesses

several remarkable properties that make it ideal for various industrial

applications Flexibility and Tear Resistance: LSR is highly flexible and

tear-resistant, providing excellent mechanical strength and longevity.

Applications of Liquid Silicone Rubber LSR is widely used in automotive applications, such as

gaskets, seals, connectors, and wire harnesses, due to its durability, chemical

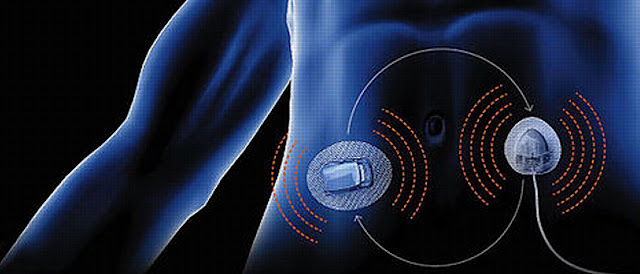

resistance, and heat resistance. Healthcare Industry LSR is extensively used in

the healthcare sector for medical device components, such as catheters, seals,

valves, and implantable devices, owing to its biocompatibility and

hypoallergenic nature. Consumer Goods LSR is found in various consumer

products, including baby bottle nipples, kitchenware, and personal care items,

due to its safety, flexibility, and ease of processing.

Industrial Equipment LSR is utilized in industrial machinery

components, such as gaskets, seals, O-rings, and protective covers, due to its

resistance to high temperatures, chemicals, and wear. Manufacturing Advantages LSR

offers several manufacturing advantages, including Precision Molding LSR can be

molded into intricate shapes with high precision, ensuring consistent quality

and dimensional accuracy.

LSR is biocompatible and hypoallergenic, making it suitable

for use in the healthcare industry. It is widely used in medical devices, such

as implants, catheters, and seals, due to its compatibility with human tissues

and fluids. Its biocompatibility ensures patient safety and reduces the risk of

adverse reactions. Liquid silicone rubber (LSR) has become a game-changer in

the world of manufacturing, offering a multitude of applications and

advantages. This versatile material has unlocked new possibilities across

various industries, revolutionizing product design and performance.

Liquid silicone rubber has established itself as a versatile

and indispensable material in various industrial sectors. With its exceptional

properties, including heat resistance, chemical resistance, electrical

insulation, and flexibility, LSR offers reliable and durable solutions for

automotive, electronics, healthcare, consumer goods, and industrial

applications. Its manufacturing advantages further contribute to improved

production efficiency and quality.

Comments

Post a Comment