Mastering Programmable Logic Controller: Unlocking Automation Potential

|

| Programmable Logic Controller |

Programmable Logic Controller (PLCs) have revolutionized the industrial automation landscape, enabling efficient control and monitoring of complex processes. These versatile devices serve as the brains behind automation systems, providing the flexibility and reliability required for modern manufacturing environments. In this blog, we will delve into the world of PLCs, exploring their capabilities, applications, and benefits.

According to Coherent Market Insights the worldwide market

for Programmable

Logic Controller market had a worth of approximately $11.6 billion in 2021, and it is

anticipated to grow to around $18.3

billion by the year 2030, with a compounded annual growth rate (CAGR) of 5.4% during the period

spanning from 2021 to 2030.

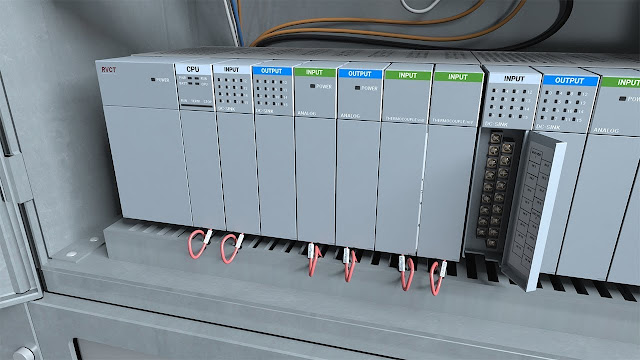

A Programmable Logic Controller is a specialized computerized

device designed to control and automate industrial processes. It is equipped with

input and output modules to interface with sensors, actuators, and other

devices. PLCs are programmed using ladder logic or other programming languages

to execute logic-based instructions and make real-time decisions.

PLCs find application in various industries such as

manufacturing, energy, automotive, and pharmaceuticals. They are used in

assembly lines, robotics, conveyor systems, and even power plants. PLCs excel

at tasks like process control, data acquisition, machine monitoring, and safety

systems. Their ability to handle multiple inputs and outputs, perform complex

calculations, and communicate with other systems makes them indispensable in

modern automation.

Flexibility: PLCs offer immense flexibility in modifying and

adapting automation processes. With the ability to change logic and reprogram

easily, PLCs allow for quick adjustments to accommodate production changes and

process optimizations.

Reliability: PLCs are known for their high reliability,

ensuring uninterrupted operation in critical environments. They are built to

withstand harsh conditions, electrical noise, and fluctuations, making them a

robust choice for industrial automation. PLC systems can be easily expanded or

modified to accommodate changes in production requirements. Additional I/O

modules, communication interfaces, or programming modifications can be

implemented without significant disruptions to the existing setup.

Diagnostics and Troubleshooting: PLCs provide extensive

diagnostics and logging capabilities, enabling efficient troubleshooting and

maintenance. They can monitor variables, detect faults, and generate alerts,

facilitating proactive maintenance and reducing downtime.

Comments

Post a Comment