The Inner Workings Of Vapor Recovery Units: A Comprehensive Guide

|

| Vapor Recovery Units |

Vapor recovery units (VRUs) play a critical role in minimizing emissions and optimizing efficiency in various industries. In this comprehensive guide, we will delve into the inner workings of VRUs, exploring their purpose, components, working principles, and benefits.

Purpose of this recovery units are designed to capture and

control this released during industrial processes, storage, and transportation.

By recovering these this, VRUs help reduce air pollution, prevent volatile

organic compounds (VOCs) from escaping into the atmosphere, and promote

environmental compliance.

The market for Vapor

Recovery Units in the global upstream sector had a valuation of US$

428.2 million in 2018. It is projected to grow at a compound annual growth rate

(CAGR) of 2.8% from 2017 to 2027, reaching a value of US$ 540.7 million by

2027.

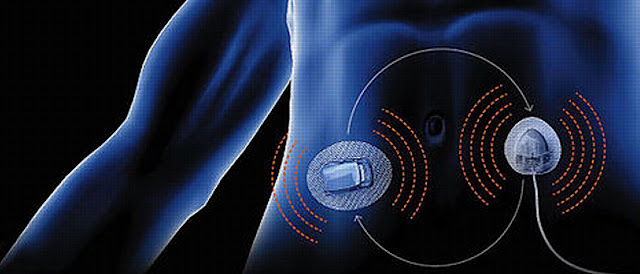

VRUs consist of several key components, including this collection

devices, storage tanks, compressors, condensers, and control systems. This collection

devices, such as hoods or vents, capture the emitted from various sources.

These collected this are then transferred to storage tanks through pipelines.

Compressors play a vital role in pressurizing the collected this, facilitating

their movement through the system. Condensers cool the, causing it to liquefy,

which can then be stored or further processed. Control systems monitor and

regulate the entire VRU operation, ensuring optimal performance and safety.

The working principle of VRUs involves a combination of

compression, condensation, and storage. As the collected this are compressed by

the Vapor Recovery Units compressor, their temperature and pressure increase.

Subsequently, the compressed this is directed to the condenser, where it undergoes

cooling, leading to the condensation of vapors into liquid form. The condensed

liquid can be stored for later use or processed as per the specific

requirements of the industry. The control system oversees the entire process,

adjusting parameters such as pressure, temperature, and flow rates for

efficient this recovery.

The implementation of VRUs offers numerous benefits to

industries and the environment. Firstly, they help industries comply with

stringent environmental regulations and reduce emissions of VOCs, contributing

to air quality improvement. Additionally, VRUs enable the recovery of valuable

hydrocarbons, minimizing product loss and maximizing profitability. By

optimizing the recovery and reuse of vapors, Vapor

Recovery Units also enhance resource efficiency and reduce the need for

additional raw materials. Furthermore, these units support sustainable

practices by promoting energy conservation and reducing greenhouse gas

emissions.

This recovery units are indispensable tools for industries

seeking to mitigate emissions, improve environmental performance, and optimize

operational efficiency. By capturing and controlling this, VRUs demonstrate

their crucial role in safeguarding the environment, promoting regulatory

compliance, and supporting sustainable practices across various sectors.

Comments

Post a Comment