Unveiling The Digital Guardian: Exploring Online Oil Condition Monitoring

|

| Online Oil Condition Monitoring |

The efficient and reliable operation of machinery and equipment is paramount. One critical factor in ensuring smooth operations is monitoring the condition of essential fluids, such as oil. This is where the online oil condition comes into play, offering a game-changing solution to enhance efficiency and reliability.

According to Coherent Market Insights the global Online Oil Condition Monitoring Market was valued

at US$

258,935.3 Thousand in 2020 and is

expected to reach US$ 430,531.31 Thousand by 2028 at

a CAGR

of 7.32% between 2021 and 2028.

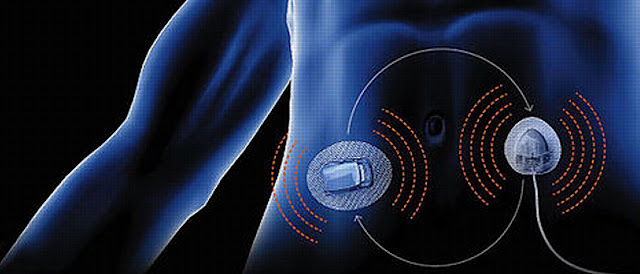

Online oil condition involves the continuous monitoring of

oil parameters, such as viscosity, temperature, contaminants, and oxidation

levels, in real-time. This is achieved through the use of sensors and advanced

analytical tools that collect and analyse data, providing insights into the

condition and health of the oil.

The benefits of online oil conditions are significant.

Firstly, it allows for proactive maintenance and predictive analysis. By

continuously monitoring oil parameters, potential issues and abnormalities can

be detected early on, allowing for timely maintenance and preventing costly

breakdowns. This proactive approach helps businesses minimize downtime,

optimize maintenance schedules, and increase the overall lifespan of machinery.

Online oil condition enables data-driven decision-making. The

real-time insights provided by the monitoring systems allow businesses to make

informed decisions regarding oil changes, lubrication schedules, and overall

equipment performance. This not only maximizes operational efficiency but also

optimizes resource allocation and reduces unnecessary maintenance costs. This

ensures that machinery operates within safe limits, minimizing the risk of catastrophic

failures and accidents that could harm personnel or the environment.

Online oil condition monitoring contributes to sustainability

efforts. By optimizing oil usage and reducing unnecessary oil changes,

businesses can minimize waste and reduce their environmental footprint.

Additionally, the ability to detect and address issues early on helps in

preventing oil leakage and spillage, further promoting environmentally

responsible practices. The online oil condition monitoring is witnessing significant

growth, driven by advancements in sensor technology, data analytics, and the

increasing demand for operational efficiency.

The Online Oil Condition Monitoring is

revolutionizing the industrial landscape by unlocking efficiency and

reliability. With real-time monitoring and data-driven insights, businesses can

proactively address maintenance needs, optimize performance, enhance safety,

and contribute to sustainability efforts. Embracing online oil condition is no

longer an option but a necessity for businesses seeking to stay competitive and

achieve operational excellence in the dynamic and demanding industrial

environment.

Comments

Post a Comment